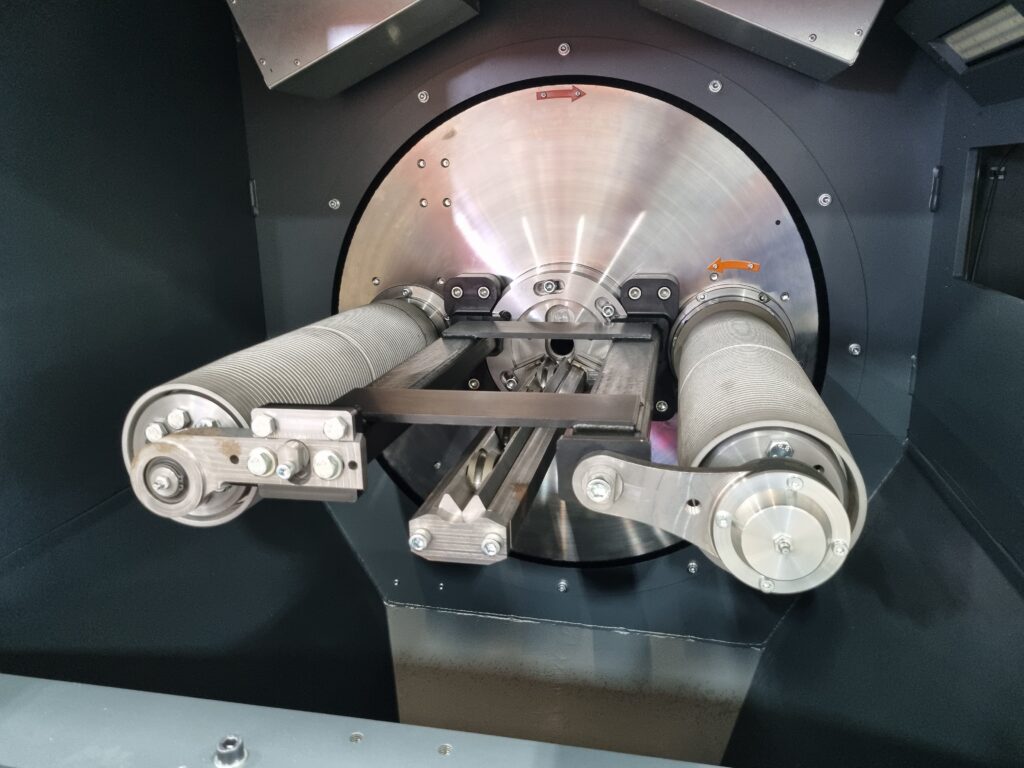

Sandpaper belt grinding

6 February 2024

The latest trend in ‘coil-to-bar’ market

Wire grinding up to 34mm with high speed. Increasingly, customers are transitioning from chemical pickling to mechanical descaling through sandpaper belt grinding. The sanding method not only saves a significant amount of money but is also more environmentally friendly and enhances working conditions.

Especially in the coil-to-bar market, we observe a substantial shift toward mechanical descaling. For instance, surface defects can be eliminated, and the surface roughness can be adjusted to fit your process through sandpaper belt grinding.

Many customers want to utilize the properties of the wire’s core and, therefore, remove the outer layer of the wire (wire-rod). This can be achieved through shaving, but sanding presents a more cost-effective solution. Many manufacturers are concerned that the heat introduced into the material during the process will lead to material hardening. However, this only occurs with inappropriate machines and the wrong consumables (sanding belts). At WiTechs, we can provide you with the right machines to employ the economical sanding method without introducing excessive heat into the material. This can result in saving hundreds of euros/dollars per metric tonnage. If you want to be progressive for your process with the latest developments that are also very

good for the environment; choose the best, choose WiTechs!